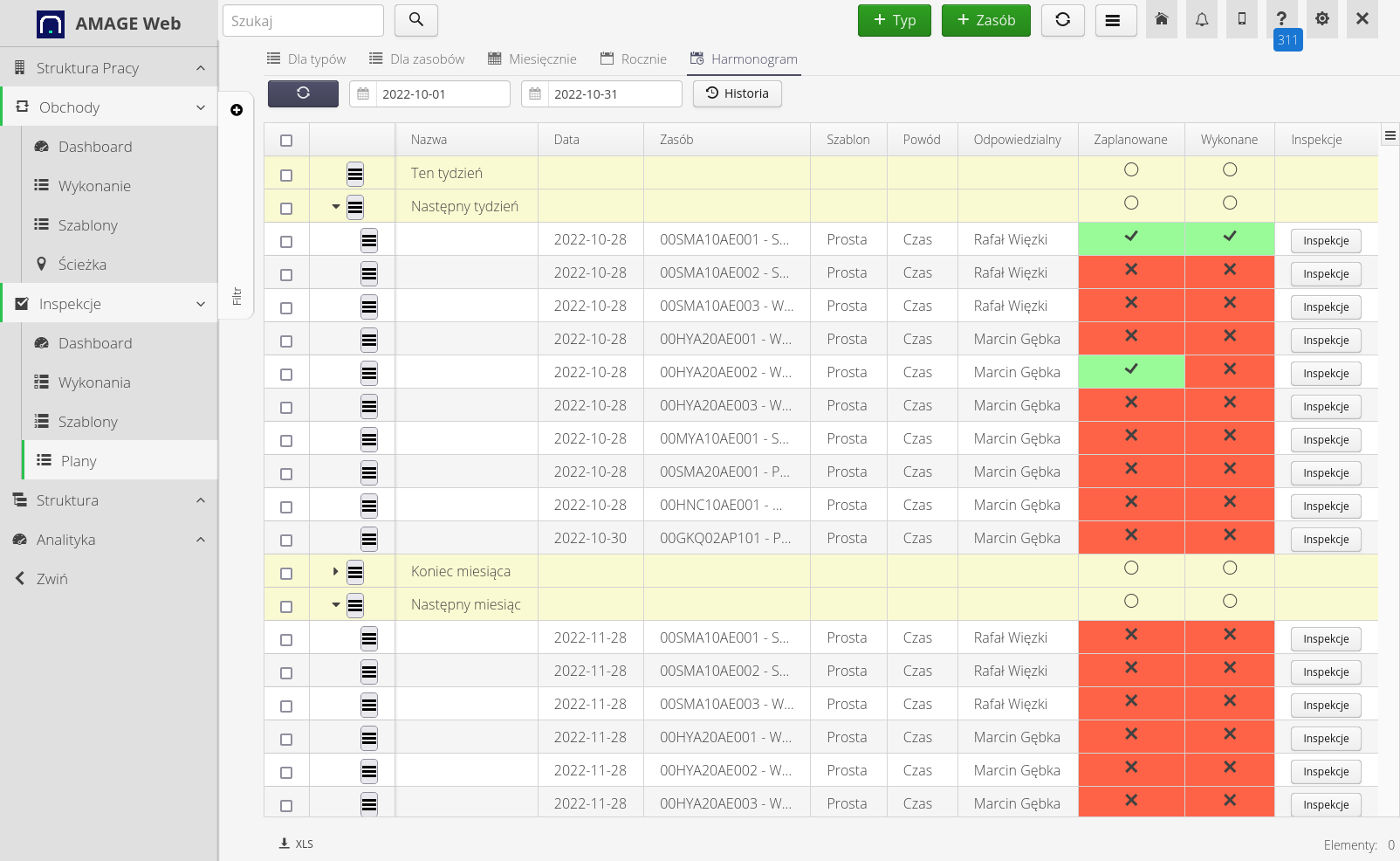

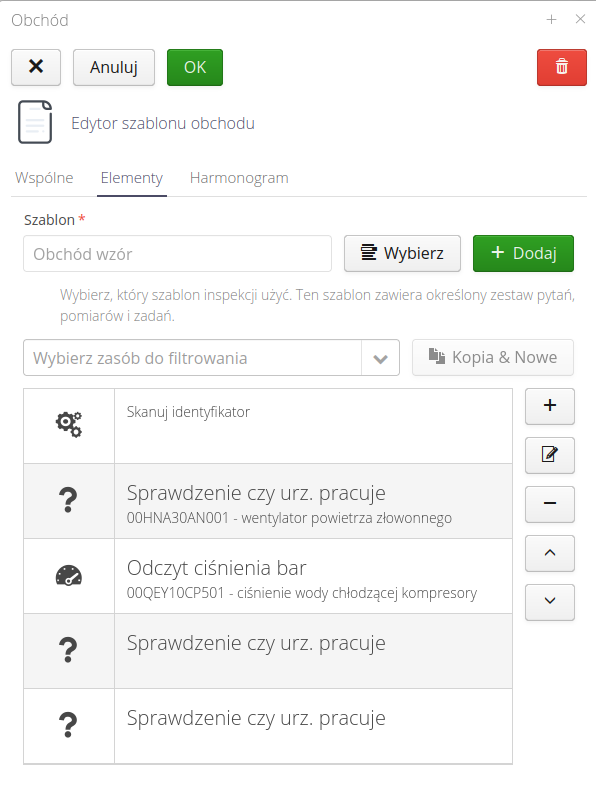

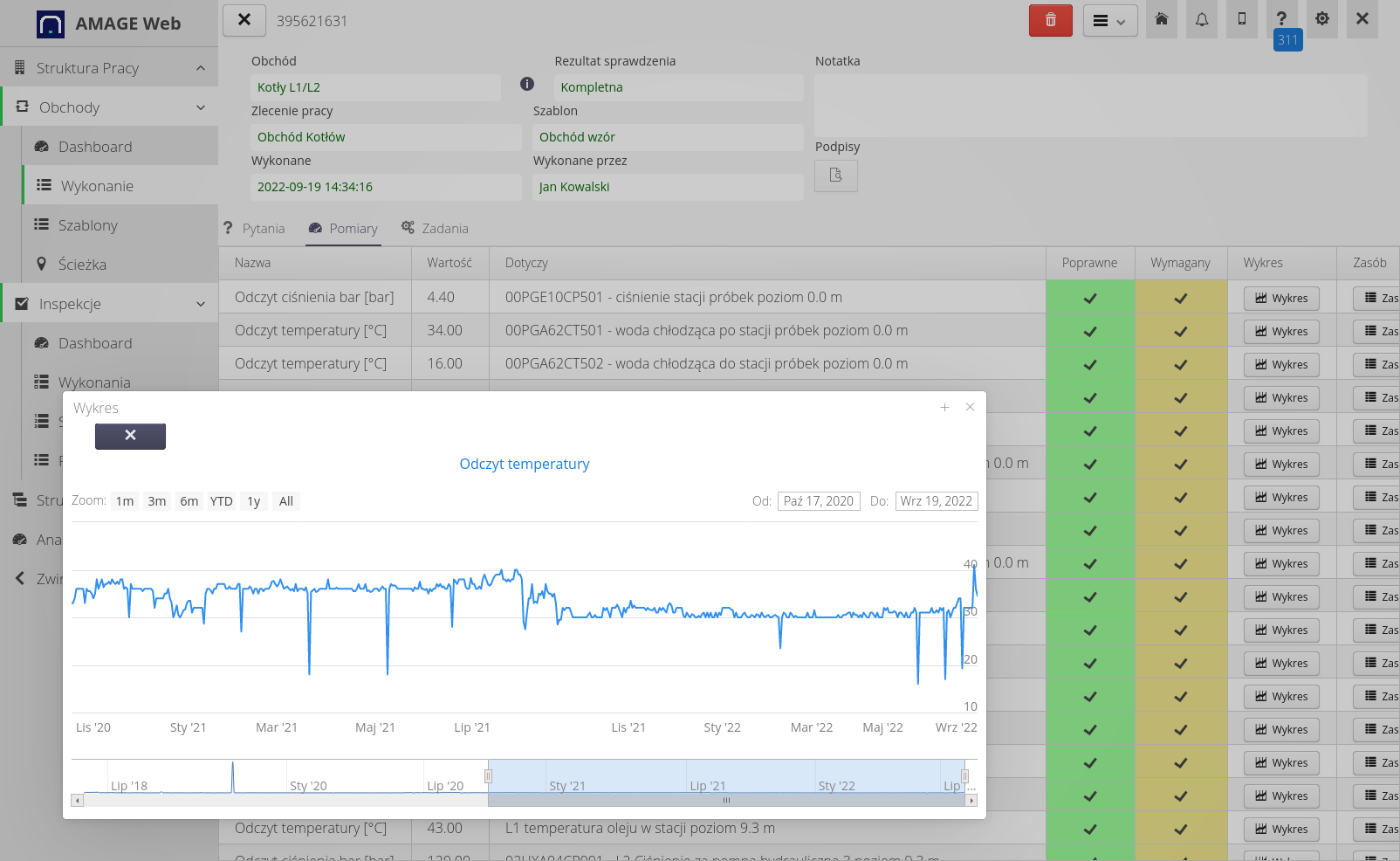

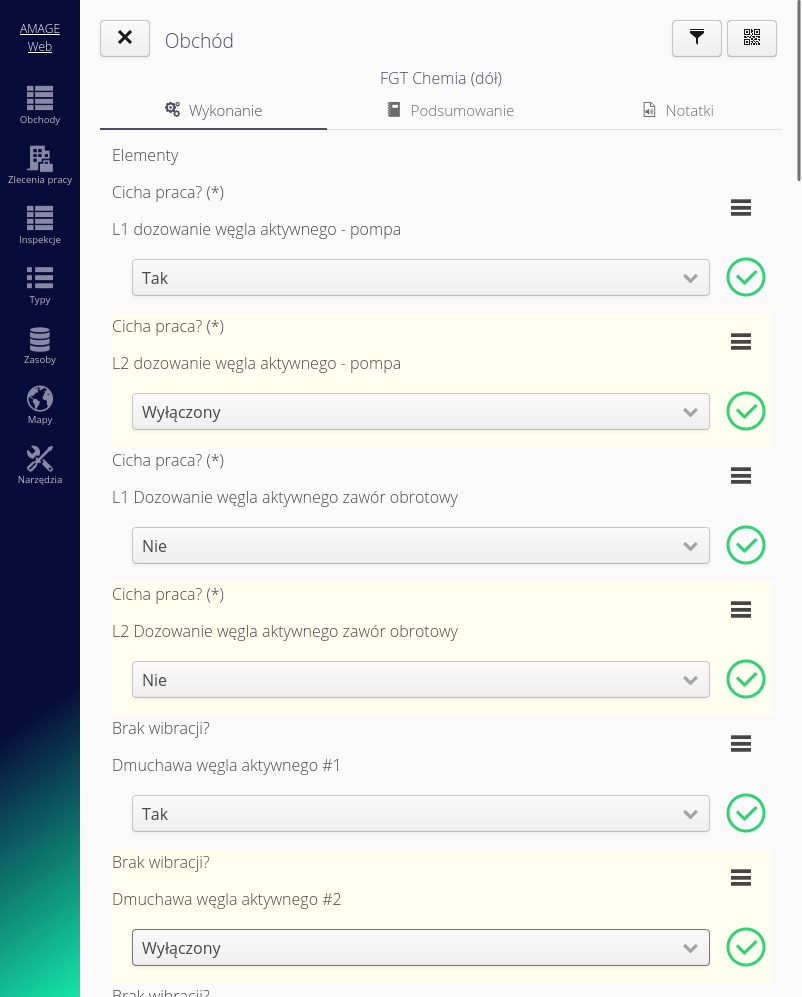

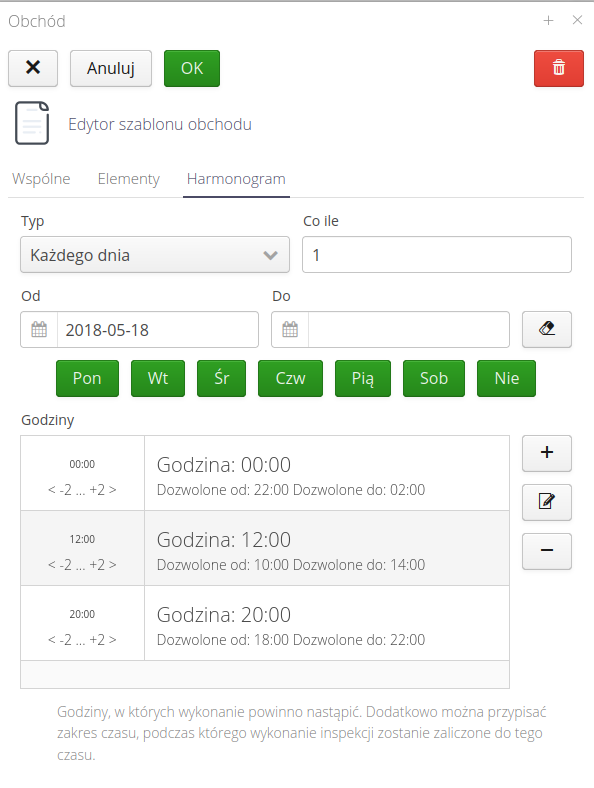

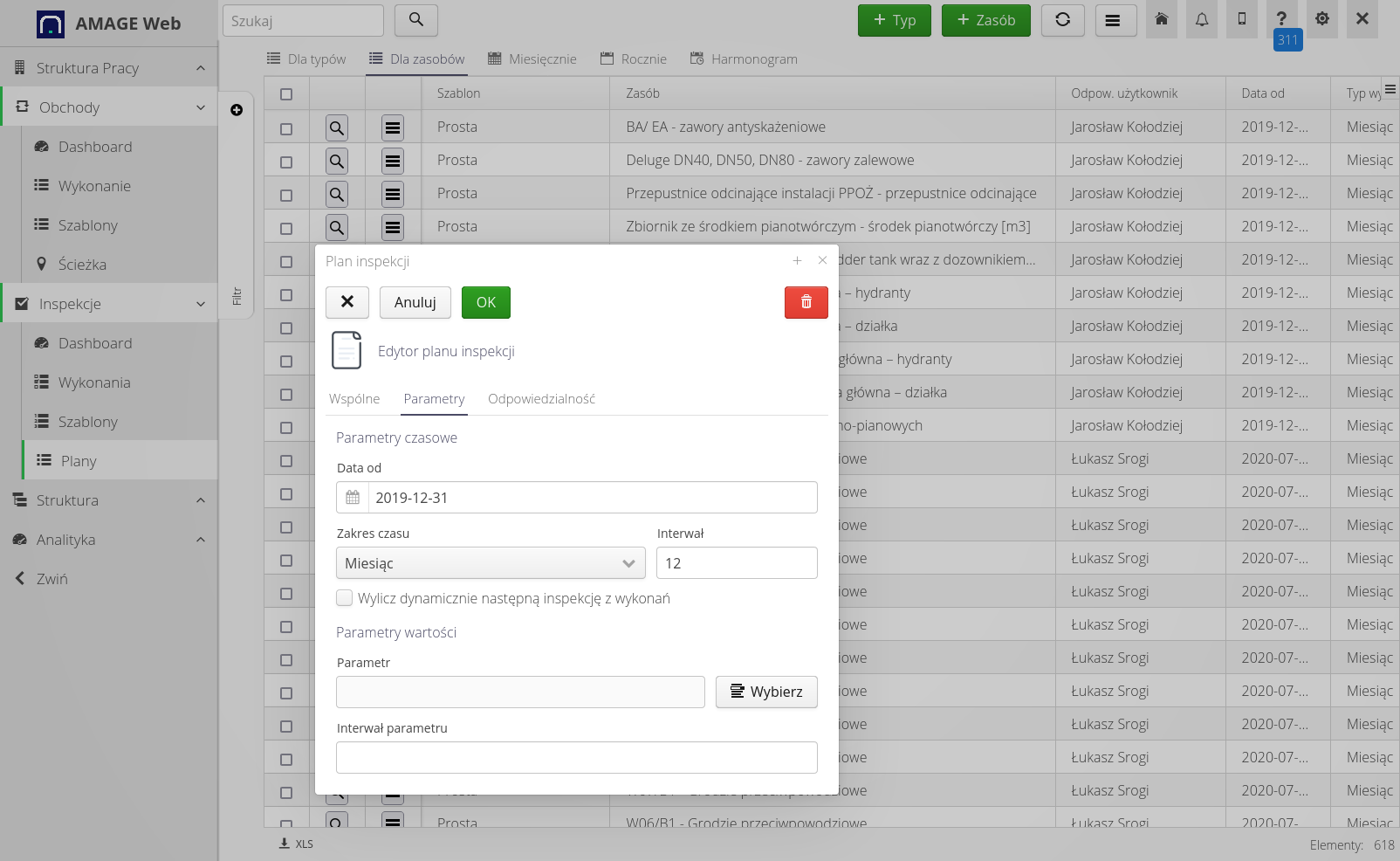

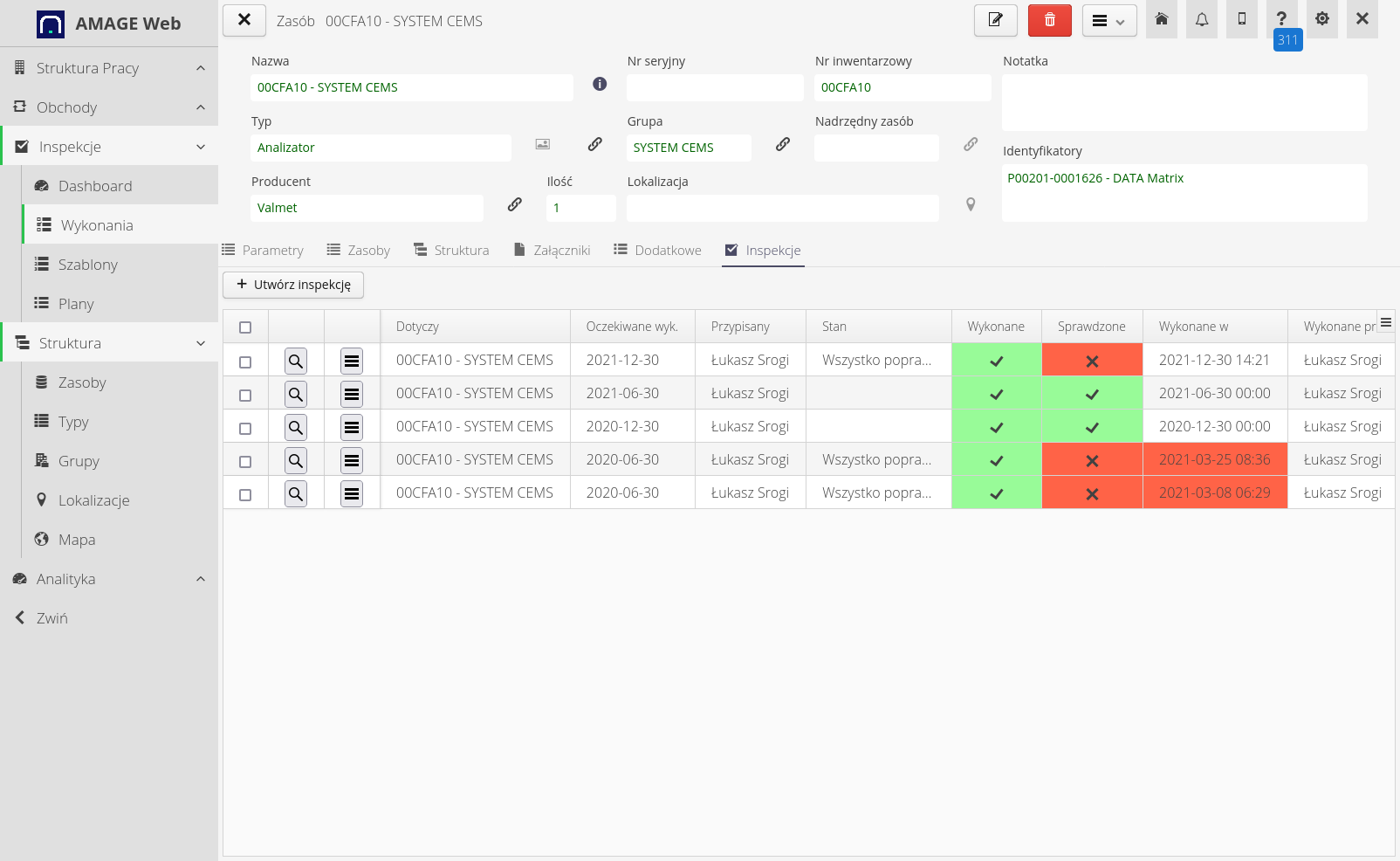

- Time and parametric rules (hours of operation)

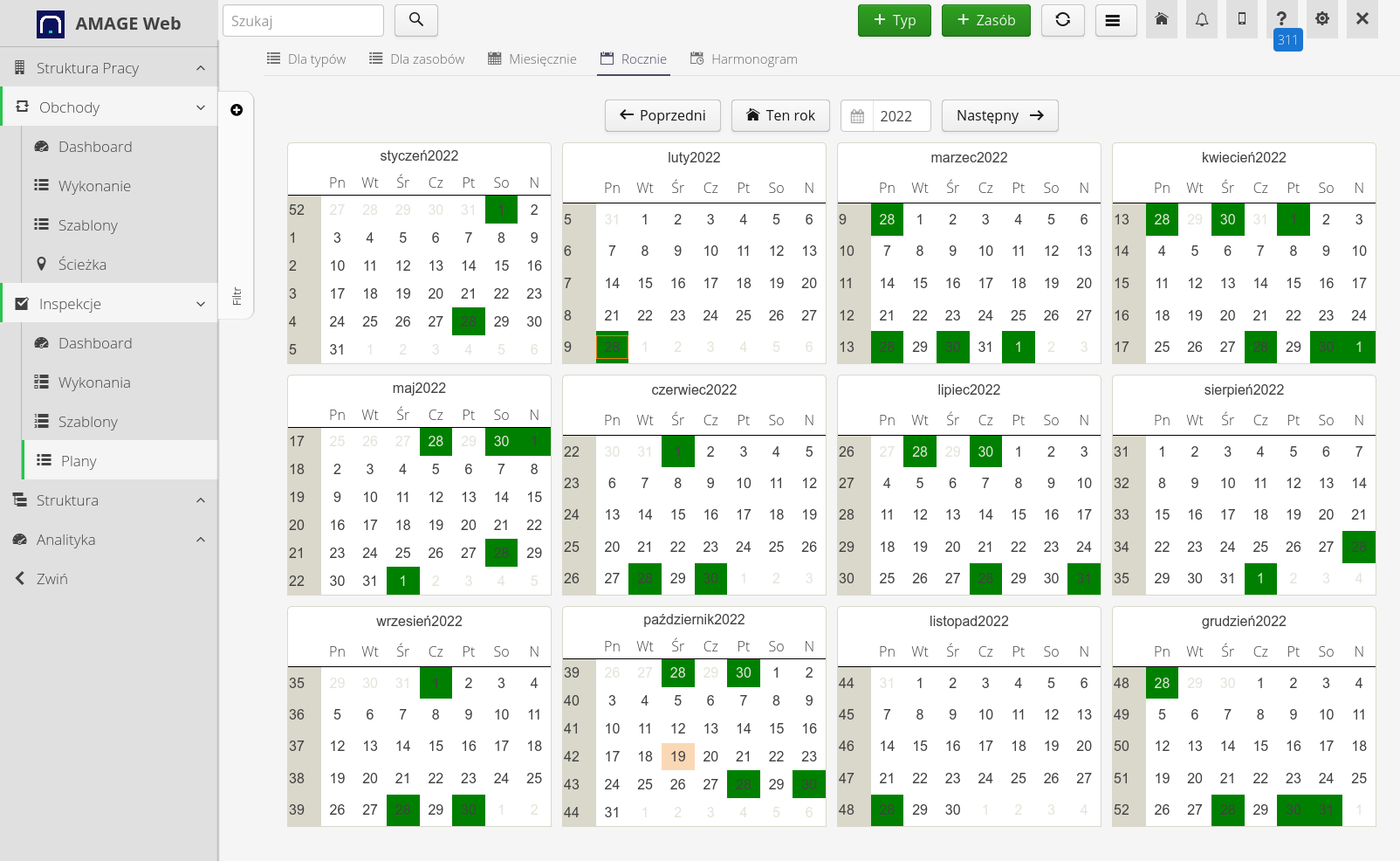

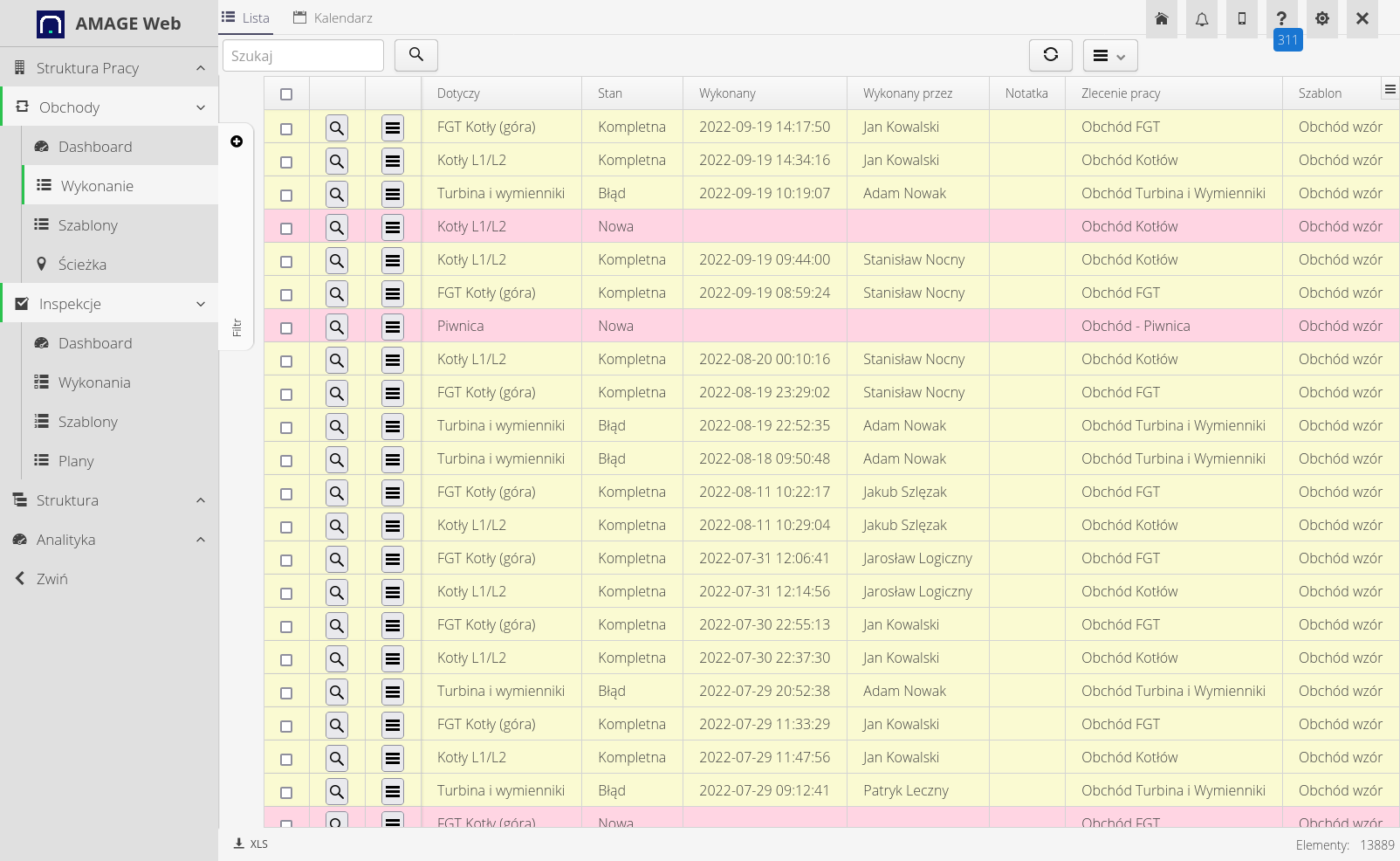

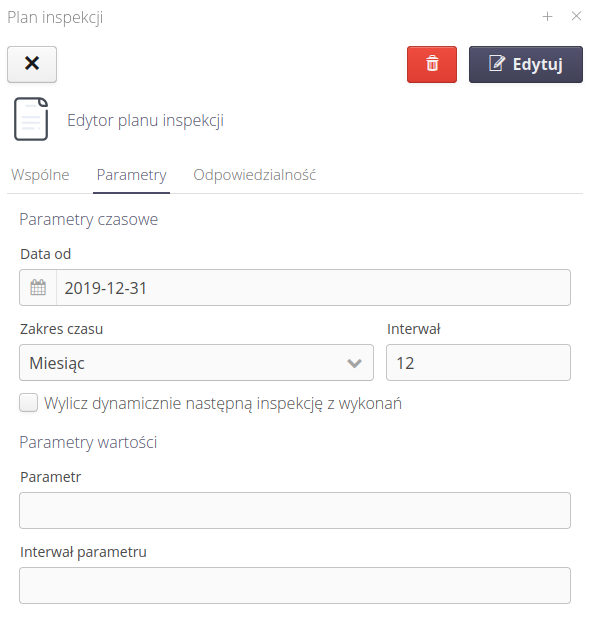

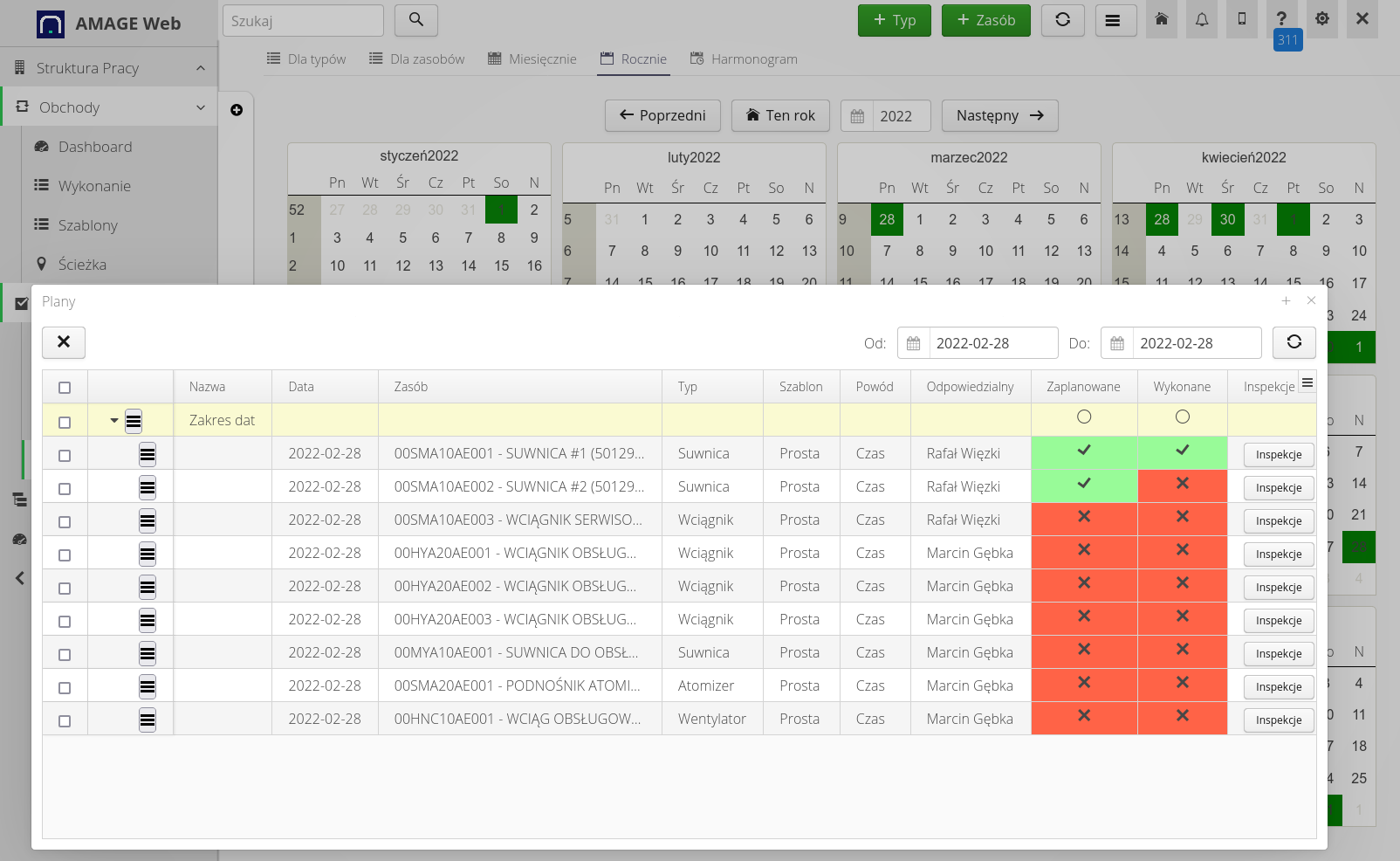

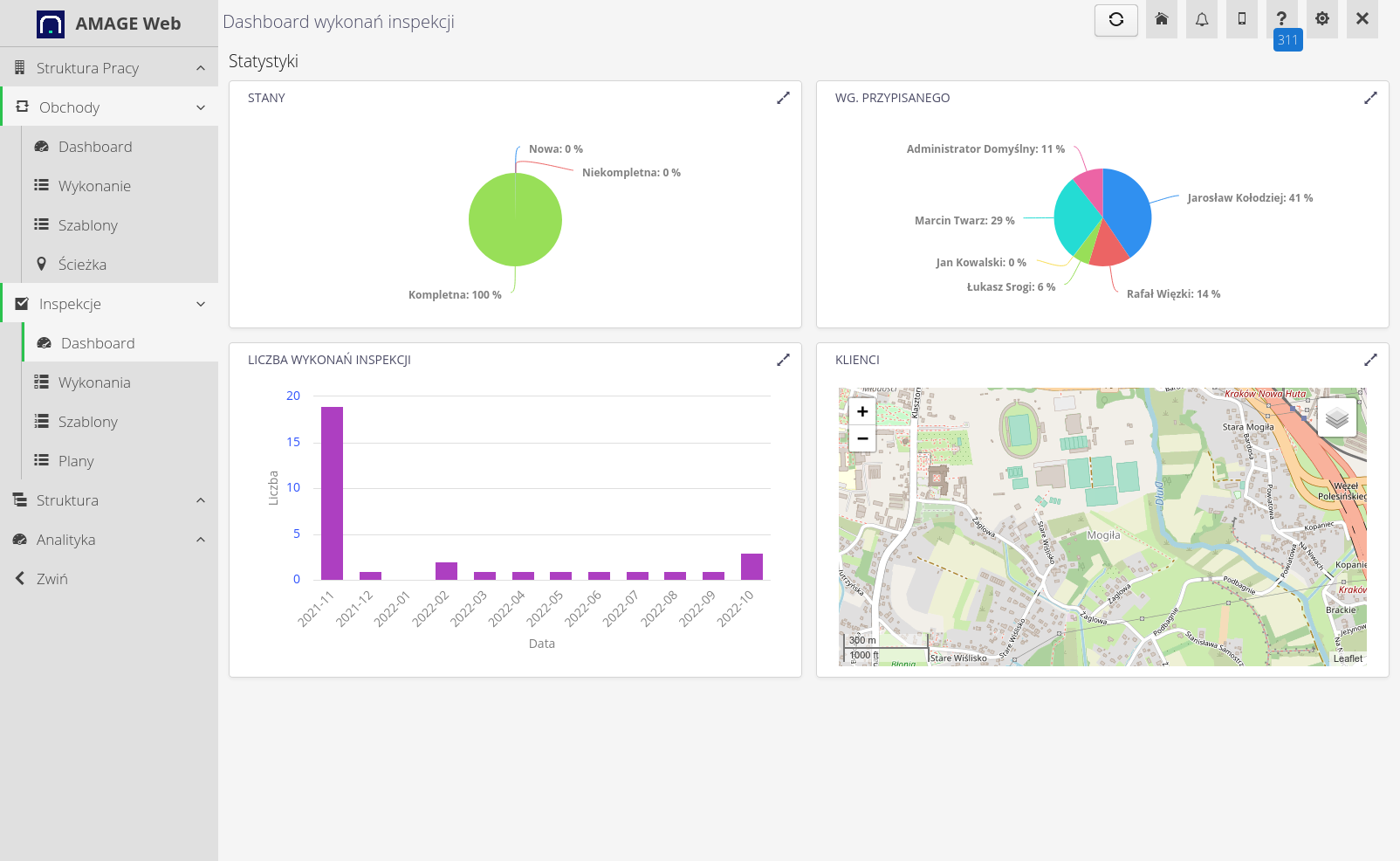

- Schedule with any frequency of execution (day, week, month, year)

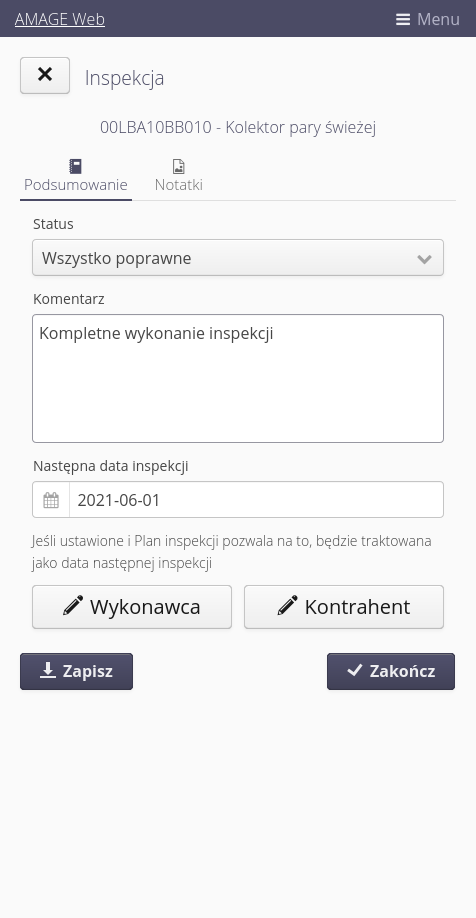

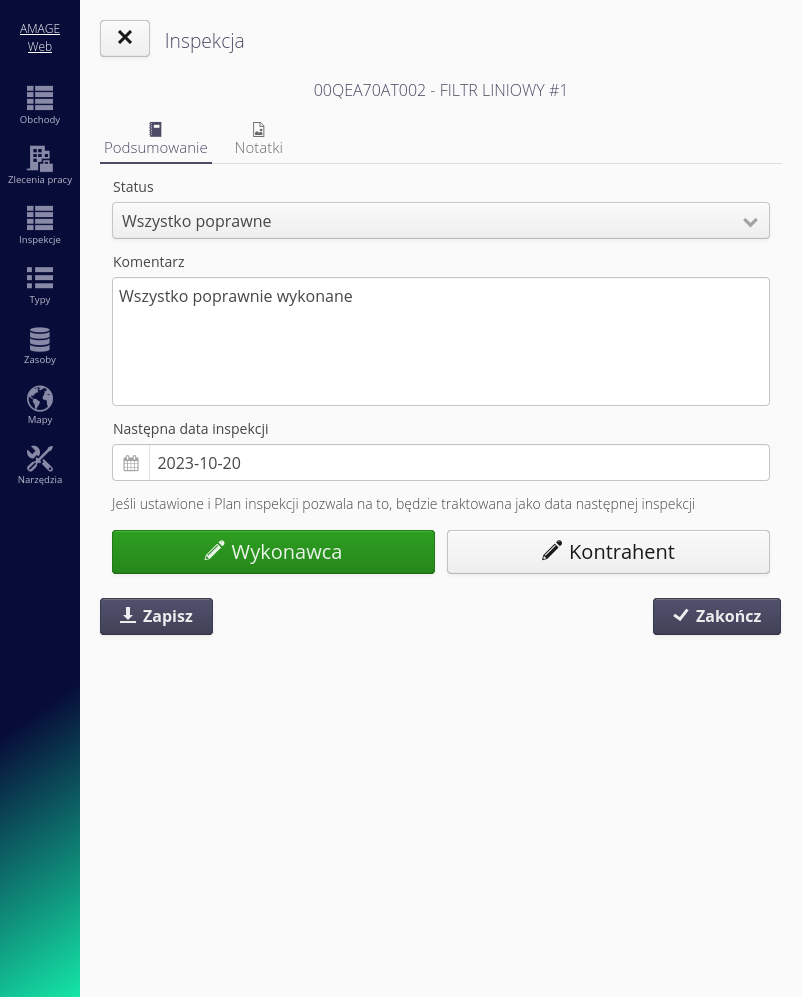

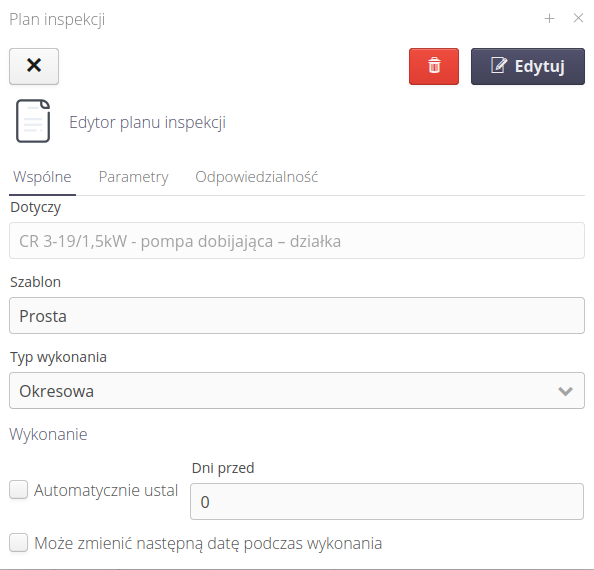

- Dynamic calculation of the next activity based on completed inspections

- Parametric Schedule considering any machine parameter (e.g., hours of operation)

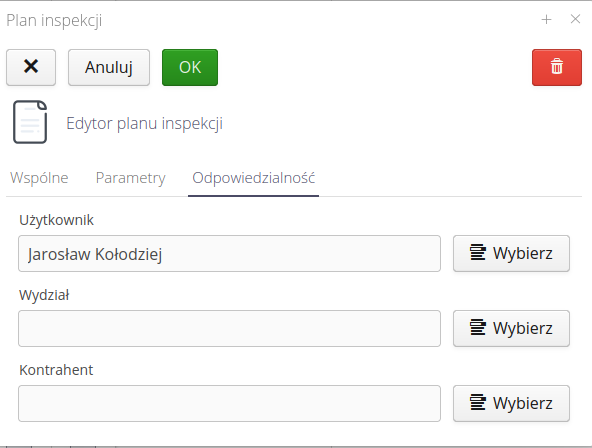

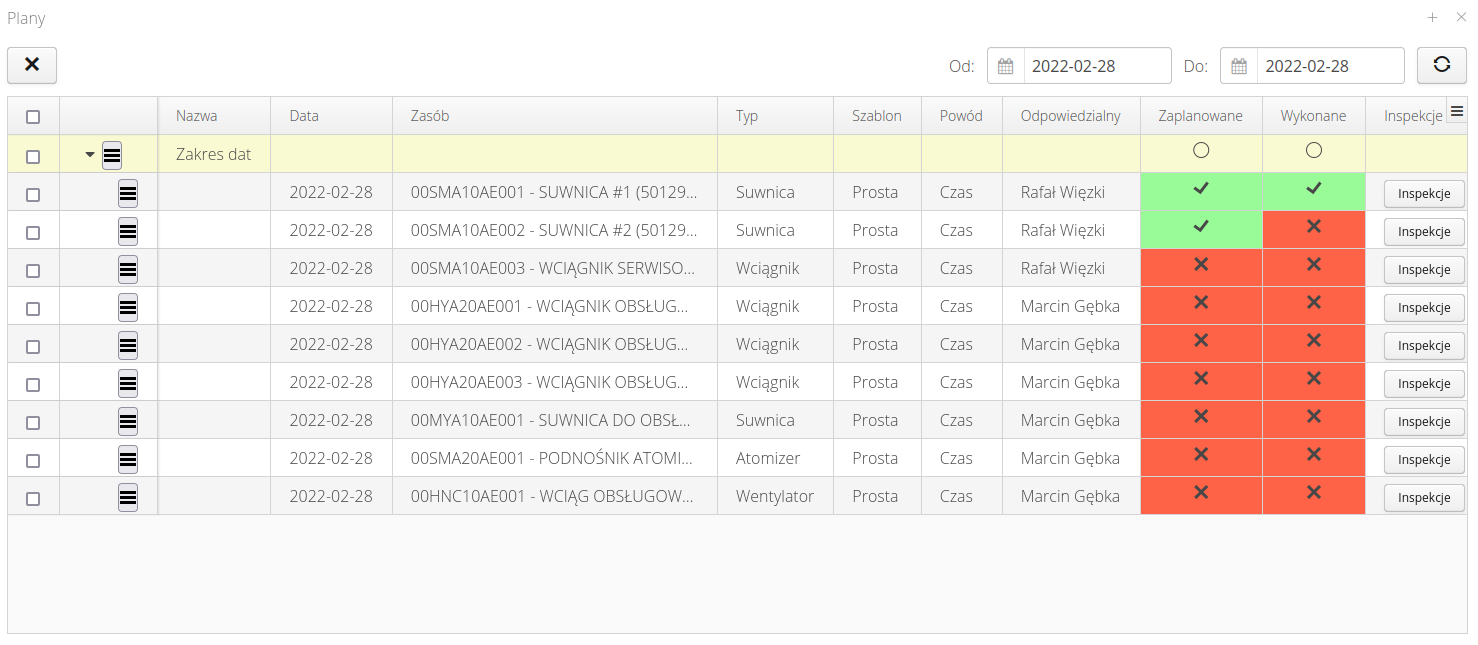

- Assigning the execution to individuals, departments, or subcontractors (external companies)

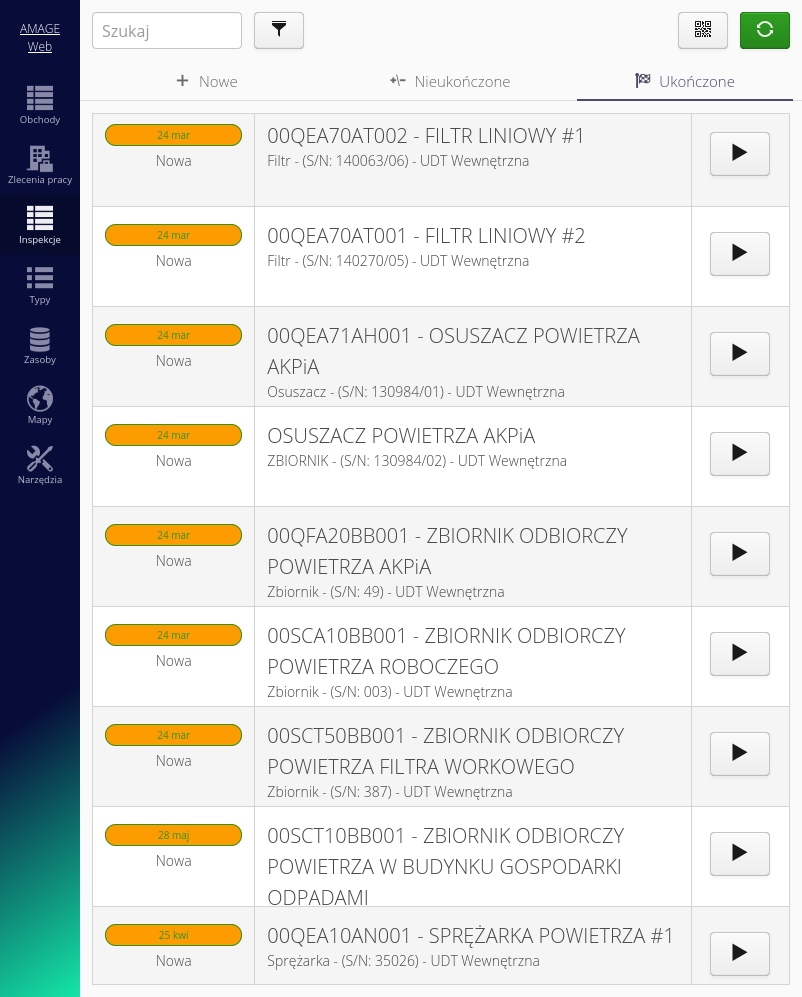

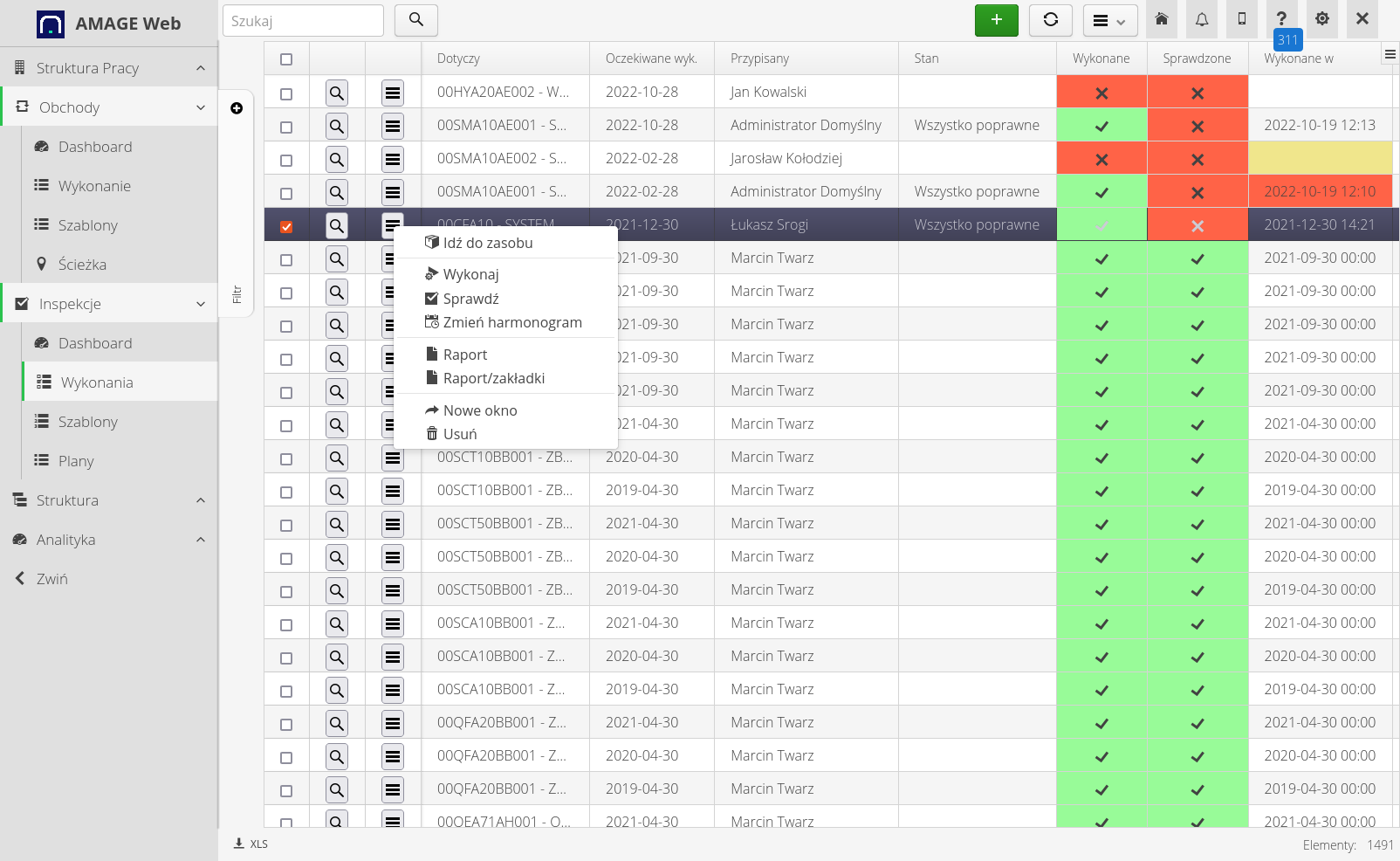

- Auto-generating orders to perform inspections in advance (e.g., 5 days before the scheduled date)

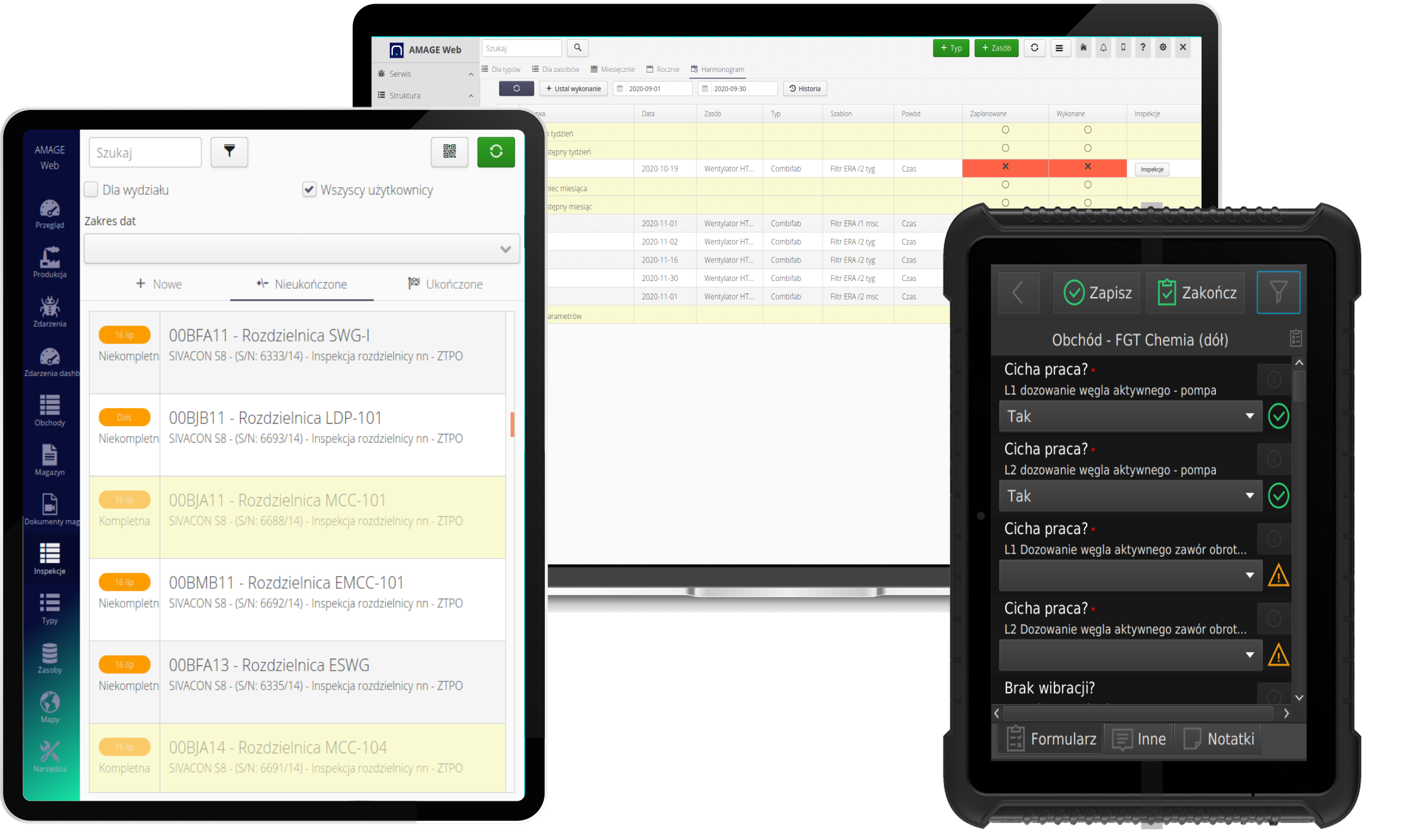

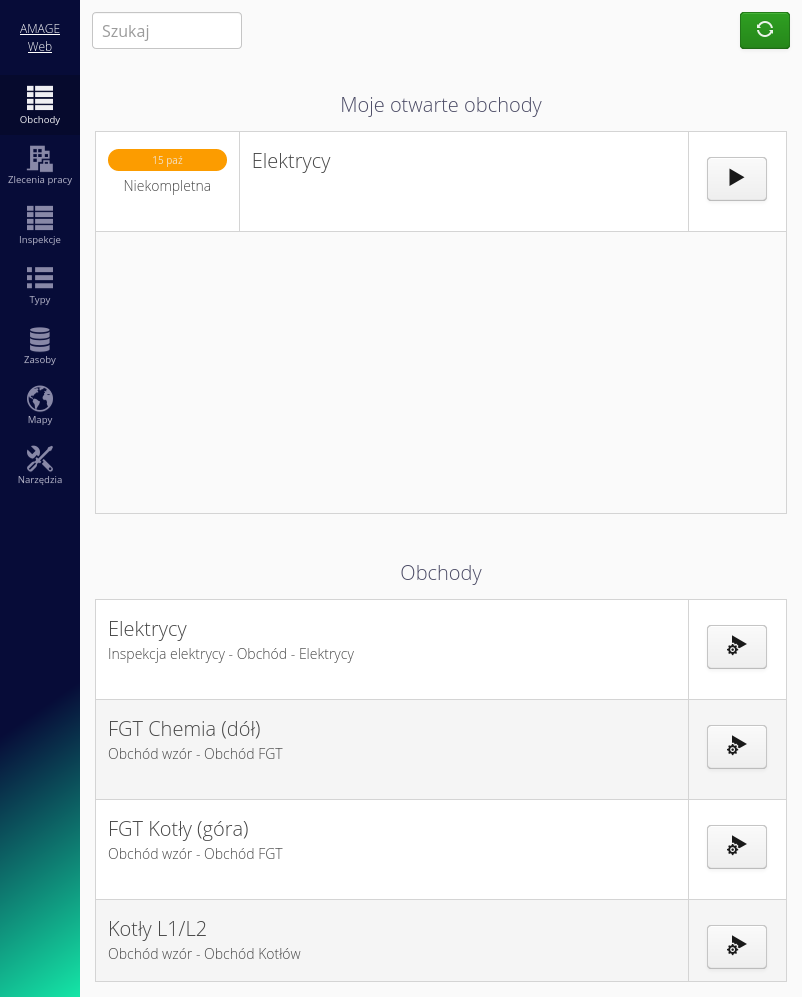

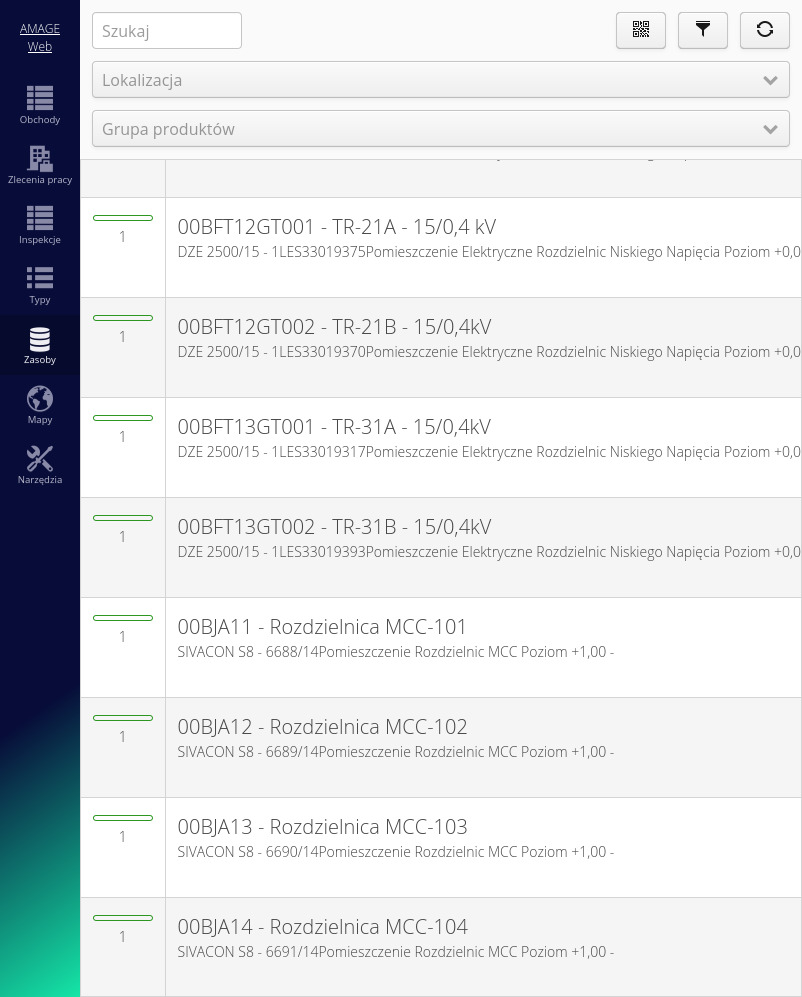

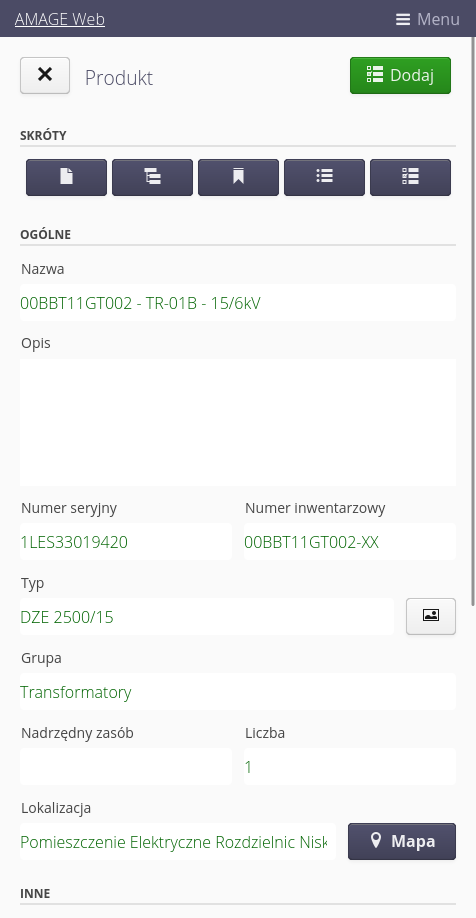

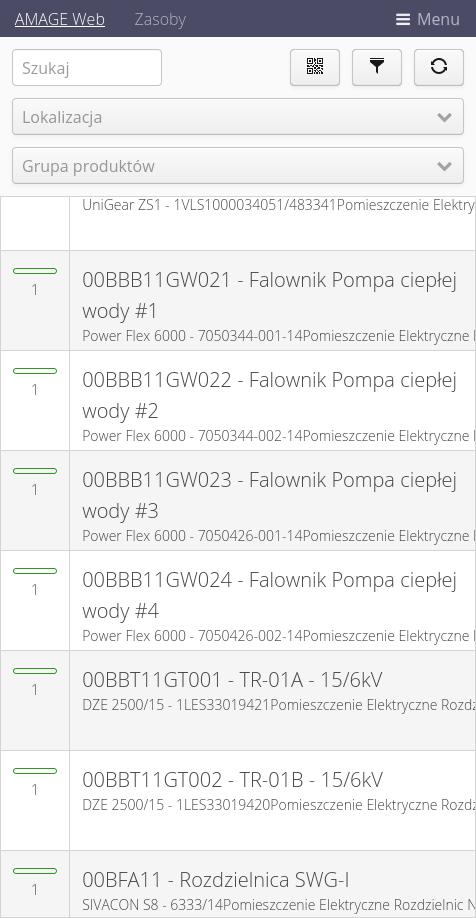

Quick Activation

The solution in the form of instant access through the AMAGE24 web platform – no software installation or time-consuming configuration.